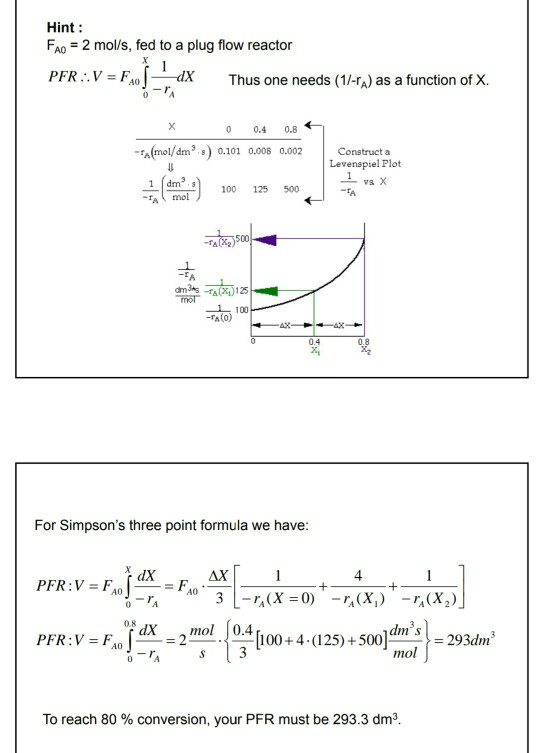

plug flow reactor example problem

Given that the system is gas phase and isothermal determine the reactor volume when X 08 X e. Append dP return dY define initial.

Mole Balance On A Plug Flow Reactor Youtube

529 yields c0 dc c0 c 1 τ t0dt Rewritten as.

. Chlorine concentration which must be added to insure that there is detectable chlorine at PFR exit detection level C L 005 mgL 1. Sum x f Ftot for f in F T H Cp r reaction_model x model_param T P dH calc_DeltaH r dP -dpdz dY r dY. No radial variation in reaction rate concentration.

Given that the system is gas phase and isothermal determine the reactor volume when X 08 X e. Plug Flow Reactor Example This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above. Steady-state mass balance on cells X L X o exp-k d 1k dlnX o X L 15hrln10 6103 14 hr V Q 025 m33.

Mass transfer can also be a problem. Two reactors are available an 800 dm 3 PFR that can only be operated at 300 K. - Selection from Problem Solving in Chemical and Biochemical Engineering with POLYMATH Book.

This implies for example that if a 20-m reactor of fixed diameter is required to achieve a given conversion the same conversion and capacity can be achieved by running. Gas phase reaction 4A B R S is performed in a plug flow reactor. A 2B 2D r A -25C A05 C B mol L -1 min -1.

This implies turbulent flow and higher energy costs if packing is used. Plug flow reactors are unique in the sense that operation in parallel or series give the same conversion if the space time is held constant. In the case of tube flow the accepted ideal is the plug-flow reactor in which it is assumed that there is no mixing in the axial flow direction but perfect mixing in the directions transverse to this.

Chemical Reaction Engineering Plug-Flow Reactor with Volume Change During Reaction Concepts Demonstrated Calculation of conversion in a gas-phase isothermal plug-flow reactor at constant pressure for a reaction. Since the reactants and products are in vapor phase click on the vapor only option. 1Set up the table for a flow reactor at 6 atm and 1110K for the reaction.

C 2H 4 H 2 Solution Species Flow into reactor Change Leaving reactor Leaving concentration C 2H 6 A F A0 F A0X F A01 X C A C A0 1 X 1 X C 2H 4 B F B0 F A0X F A0 B X C B C A0 B X 1 X H 2 C F C0 F A0X F A0 C X C C C A0 C X 1 X The unknowns in the concentration expression. 3 The Design Problem The liquid phase reaction between salicylic acid and acetic anhydride in the presence of an acid catalyst to form acetylsalicylic acid aspirin and acetic. For this problem the kinetic rate expression is given so select the User Specified option.

It can be shown2 that the absence of axial mixing allows the achievable reactant conversion to be maximized. Consider a simple rectangular reactor which has a gas inlet on one side an exhaust on the other and deposition on the top and bottom walls and the sample resting on the bottom surface. Vrdc dt Qc0 Qc Recalling Vr Q τ the above equation can be rewritten as 529dc dt 1 τc 1 τc0 This is the mathematical description of perfectly-mixed flow model.

The volumetric flow rate of the feed is 50 Lmin. We will now return to this example and develop an the process engineering design. EXAMPLE Gas Phase Elementary Reaction Additional Information.

The system may be either contained as in a water main oil pipeline or blood vessel or open as in a. Return-r 0 H_A-r 1 H_B r 2 H_C define the plug flow reactor model def plug_flow_reactor_gas z Y dpdz model_param reaction_model. Concentration changes with length down the reactor.

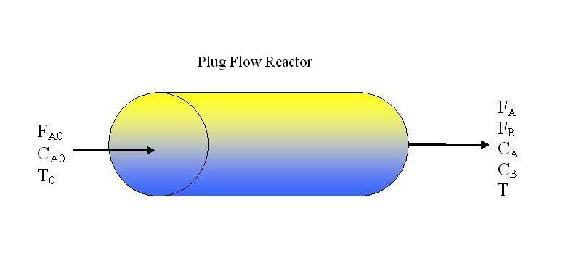

Plug Flow Reactor PFR The third general type of reactor is the Plug Flow Reactor PFR. IIIC3ai Plug flow reactors. Sum P Y -1 Ftot F.

Determine X e for a PFR with no pressure drop P P 0. The reaction takes place at 3 atm and 150C. Plug flow reactor design equation.

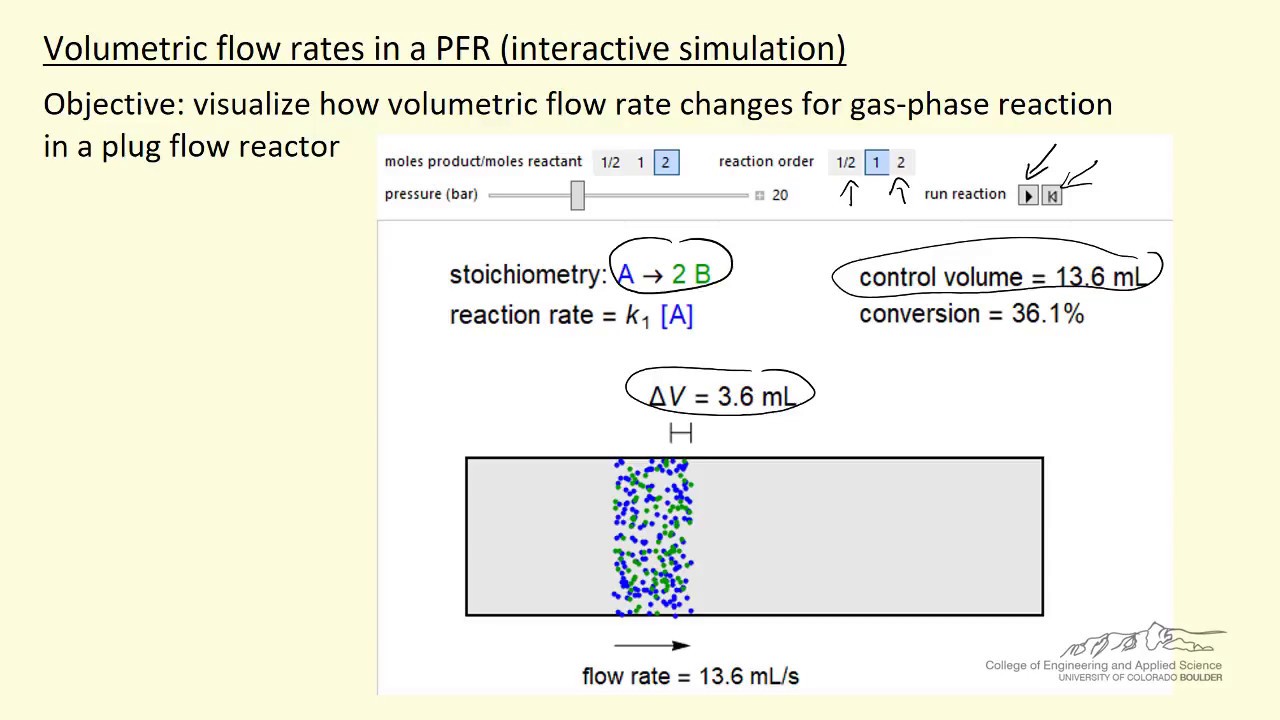

Made by faculty at the University of Colorado Boulder Department of Chemical. Pg694 This is the equation for a plug flow reactor. A shower curtain the walls of a bathtub or a canyon wall seep all.

This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above. Taking the mass balance of the tracer in the reactor gives. Continuously Stirred Tank Reactor CSTR Arranged as one long reactor or many short reactors in a tube bank.

Example Algorithm for Steps in Solving Closed-Ended Problems. To achieve desired conversions predicted by ideal design equations plug flow is required. Axial diffusion or dispersion tends to decrease residence time in the reactor.

F Y 0-2 H Y -2 F. It can be derived directly from the rate equations with the aid of. A completed case has been pre-built and is located in the file PlugFlowExhsc in the HartsookHysysSAMP403 directory though I recommend you work.

The same example problem has been worked in Aspen and Matlab. The initial condition is t 0 c 0 Integrating Eq. View Notes - Plug Flow Reactor Example from CHE 442 at Arizona State University.

Example 5 Percent Approach to Equilibrium For a reversible reaction with rate equation r L A 1 AVl6 the size function kVV of a plug flow reactor will be found in terms of percent approach to equilibrium. Plug Flow Reactors PFRs Type of Reactor. PFR example in the design of an ideal plug flow reactor pfr was considered.

Plug Flow Reactors PFRs Type of Reactor. A brief overview of plug flow reactors their properties equations and uses. A Plug Flow Reactor Plug flow is an extremely simple tool but were going to put it to use anyway.

The elementary liquid-phase irreversible reaction is to be carried out in a flow reactor. C A0 02 moldm 3 K C. Develop equations to determine plug flow reactor size for 50 conversion of reactant A.

Formation rate of R is empirically correlated by the equation B A A B R C C C C r 1 05 1 rR in molLh CA and CB in molL The plug flow reactor is fed with a flow rate of 200 kmol A h and the feeding is 50 A and 50 B. In a plug flow reactor nutrients and sometimes organisms are introduced to the reactor continuously and move through the reactor as a plug. The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C.

Up to 5 cash back Chapter 11. As the reactor described in the problem statement is a plug flow reactor PFR should be selected form the drop box. Reactor volume and flow path length L such that X L 10 3 cells100 ml 2.

Solved Example Consider The Liquid Phase Reaction A Chegg Com

Elements Of Chemical Reaction Engineering

Thoughts On Problem Solving Pfr Cstr Example

Isothermal Plug Flow Reactor Part 1 Youtube

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Elements Of Chemical Reaction Engineering

Plug Flow Reactor An Overview Sciencedirect Topics

Volumetric Flow Rates In A Plug Flow Reactor Interactive Simulation Youtube

Simulation Of Plug Flow Reactor Pfr In Aspen Hysys Lecture 64 Youtube

1 4 Continuous Flow Reactors Mole Balances In Chemical Reaction Engineering Informit

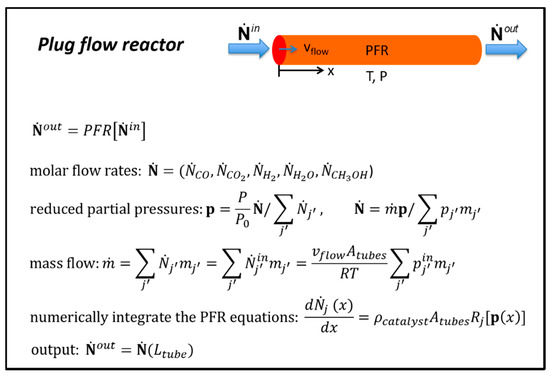

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

Plug Flow Reactor Design Equation Youtube

Matlab In Chemical Engineering At Cmu

Plug Flow Reactor Overview Youtube

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram

6 7 Ode And Excel Model Of An Adiabatic Pfr Engineering Libretexts